Early

recognition and diagnosis of problems relating to operating machinery

is cost effective. Failure to identify a small fault can lead to major

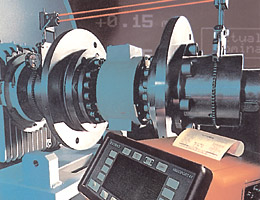

equipment breakdown. STM Rewinds provides measuring instruments for the

key areas of Machine Diagnosis, Field Balancing and Alignment.

Early

recognition and diagnosis of problems relating to operating machinery

is cost effective. Failure to identify a small fault can lead to major

equipment breakdown. STM Rewinds provides measuring instruments for the

key areas of Machine Diagnosis, Field Balancing and Alignment.

Frequency analysis of vibrations provides conclusions to the sources

of faults such as the type and the extent of damage of individual machine

components. Typical faults that can be identified through frequency analysis

include:

- Unbalance

- Misalignment and coupling errors

- Bearing and gearing errors

Machine Diagnosis enables an entire machine to be evaluated, symptoms

are recognised through developing damage, failure sources and damaged

components are identified.

Unbalance is the most common source of managing faults. Correction of

this problem is carried out on site, without major disassembly of the

machine, by a single technical operator using one instrument.

All these processes are carried out by one integrated machine, operated

by one technical engineer, on site. This procedure can be initialised

anywhere in the world.